Call Us

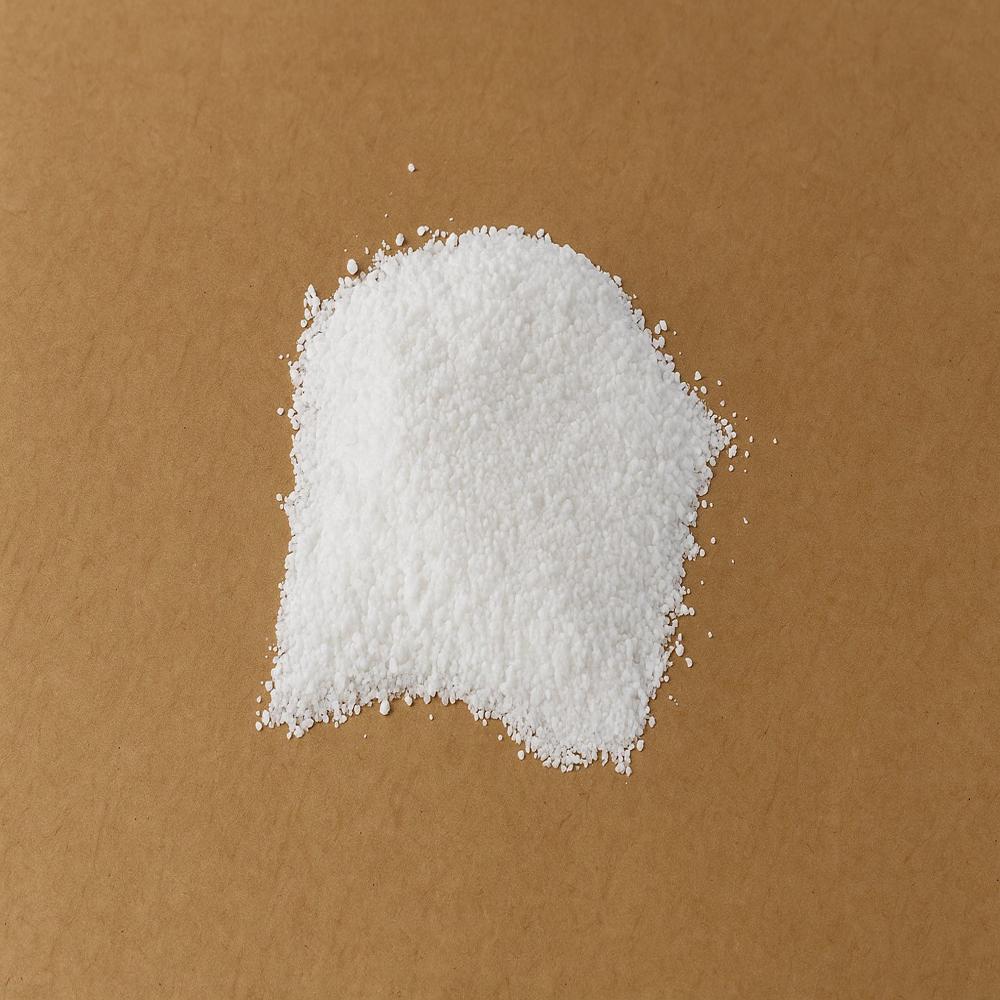

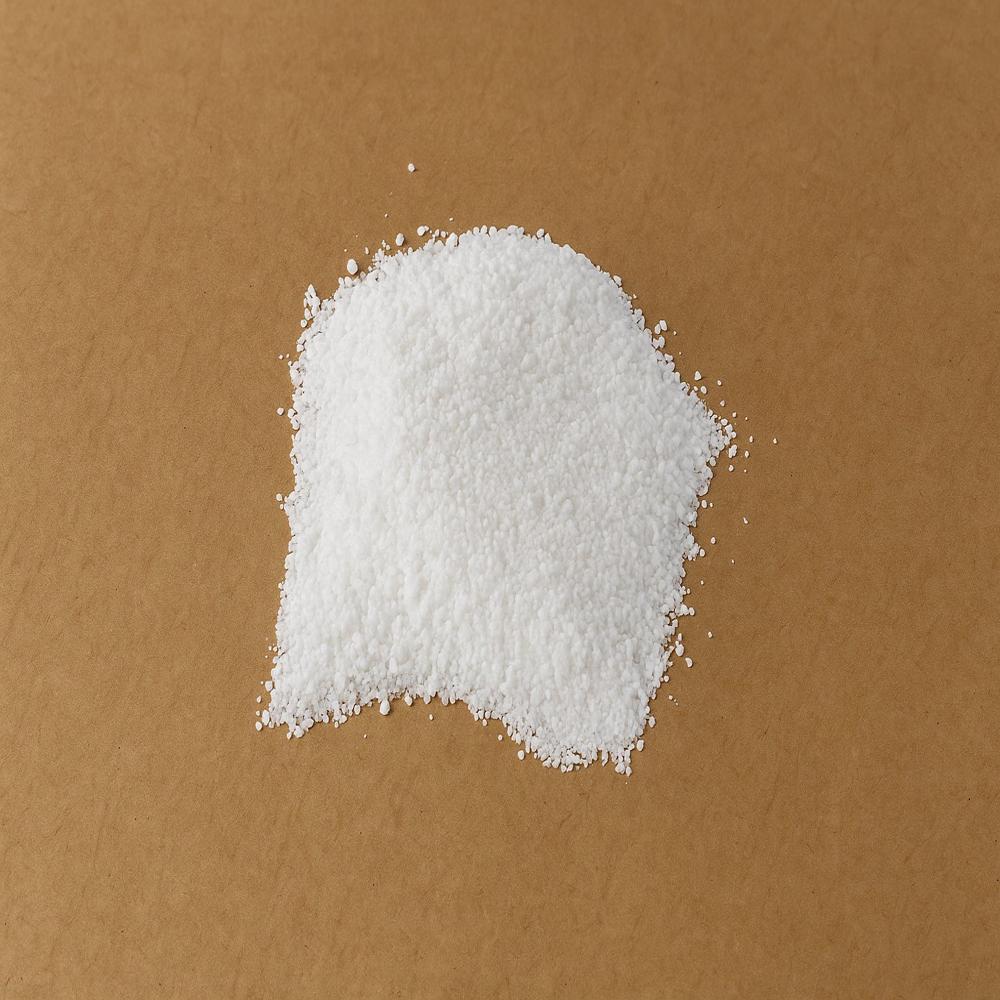

High Purity Benzoyl Peroxide Granular

240.00 INR/Kilograms

Product Details:

- Shape Granules

- Product Type ORGANIC PEROXIDE

- Grade GRANULAR

- Purity 98%

- Storage Room Temperature

- Shelf Life 12 Months

- Taste Odorless

- Click to View more

X

High Purity Benzoyl Peroxide Granular Price And Quantity

- 20 Kilograms

- 240.00 INR/Kilograms

High Purity Benzoyl Peroxide Granular Product Specifications

- Granules

- ORGANIC PEROXIDE

- 98%

- GRANULAR

- 12 Months

- Room Temperature

- Odorless

- WHITE GRANULARS

- Used as a curing and vulcanizing agent Initiates polymerization in rubber compounds Improves elasticity, strength, and durability Ensures controlled and uniform rubber curing

- YES

- Granule

- Rubber

High Purity Benzoyl Peroxide Granular Trade Information

- EX-BHIWANDI DEPO

- Cash Advance (CA), Cash in Advance (CID)

- 5000 Kilograms Per Month

- 10 Days

- If order is confirmed we will reimburse the sample cost

- 20KGS BAGS

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Maharashtra

- ISO, FSSAI, HALAL, KOSHER

Product Description

Our Benzoyl Peroxide Granules are a safe, easy-to-handle form of benzoyl peroxide widely used in different industries. In granular form, it provides better stability, controlled release, and safer storage compared to powder. It acts as a polymerization initiator, curing, and cross-linking agent, helping improve the strength, durability, and performance of rubber, plastics, and other specialty formulations. With consistent activity and reliable quality, it is ideal for industrial use.

Main Function

-

Works as a curing and vulcanizing agent

-

Initiates polymerization in rubber processing

-

Improves elasticity, durability, and heat resistance

Features

-

Safe granular form for easy handling

-

High purity and reliable activity

-

Provides controlled and uniform curing

-

Better stability than powder

Uses

-

Vulcanization of synthetic and natural rubber

-

Cross-linking in elastomers

-

Enhancing rubber strength and flexibility

Applications

-

Rubber products like tires, hoses, seals, gaskets

-

Industrial rubber goods

-

Specialty elastomer compounds

Enhancing Rubber Performance

Benzoyl Peroxide Granular ensures controlled and uniform curing of rubber by initiating the polymerization process. This leads to superior mechanical properties including increased elasticity and durability, making it a preferred agent in rubber manufacturing processes.

Safe Handling and Storage Guidelines

While Benzoyl Peroxide Granular offers substantial processing advantages, it must be stored properly at room temperature, away from direct sunlight and contaminants. Its toxic nature necessitates the use of protective gear during handling to guarantee safety in industrial environments.

FAQs of BENZOYL PEROXIDE GRANULAR:

Q: How is Benzoyl Peroxide Granular used in the rubber industry?

A: It is employed as a curing and vulcanizing agent to initiate the polymerization process in rubber compounds, leading to improved curing control and enhanced final product properties.Q: What are the primary benefits of using Benzoyl Peroxide Granular in rubber applications?

A: This product improves the elasticity, strength, and durability of rubber by ensuring even, reliable curing and promoting optimal polymerization during manufacture.Q: When should Benzoyl Peroxide Granular be added during the rubber production process?

A: The product is typically incorporated during the compounding stage before curing, allowing it to efficiently initiate polymerization and achieve desired mechanical characteristics in the final rubber product.Q: Where should Benzoyl Peroxide Granular be stored?

A: It should be stored at room temperature in a dry place, away from direct sunlight and incompatible materials, to maintain its stability and effectiveness over a 12-month shelf life.Q: What precautions are necessary due to the poisonous nature of Benzoyl Peroxide Granular?

A: Personnel should wear appropriate protective equipment such as gloves, goggles, and masks while handling the granules, and ensure good ventilation in the working area to mitigate risks.Q: How does Benzoyl Peroxide Granular differ from other curing agents in rubber processing?

A: With high purity (98%) and granular form, it offers reliable dispersion and more consistent curing control compared to some liquid or powder formulations, contributing to uniform product quality.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Plastic And Rubber Chemicals' category

Back to top

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese